What is the RGB Color Model? A Precise Guide

Do you run a business that sells products? If you answer yes, you must be quite familiar with the importance of printed box packaging. As a business owner, you know the impact of high-end printing to get people’s attention and lead conversions.

Two choices cross our minds when we talk about color printing, one is CMYK and the other one is RGB. You may have tried CMYK printing for custom box packaging but do you know that manufacturers avoid using RGB printing for custom box printing?

Curious to know why? Read on to learn what is RGB Color Model and why it is avoided in printing.

Why Strategic Placement of Colors Are Important?

The strategic placement of color in package design can make a huge impact on your branding and sales. Think of any brand, you can immediately visualize their products with unique colors. Custom Packaging printing of every brand varies and is unique. Say it head and shoulders or Pantene, Pepsi, Coca-Cola, and KFC.

You will see every product has its unique branding colors that do not match with any other product in the market. That is why branded colors for your packaging are highly significant as they define your brand identity.

As we mentioned, two different color modes are employed for box printing which are RGB and CMYK. However, the order in which you'll employ them all depends on the number of decisions you'll need to make.

That is before having your Kraft Boxes designed and manufactured. Now let's get started.

What is the RGB Color Model?

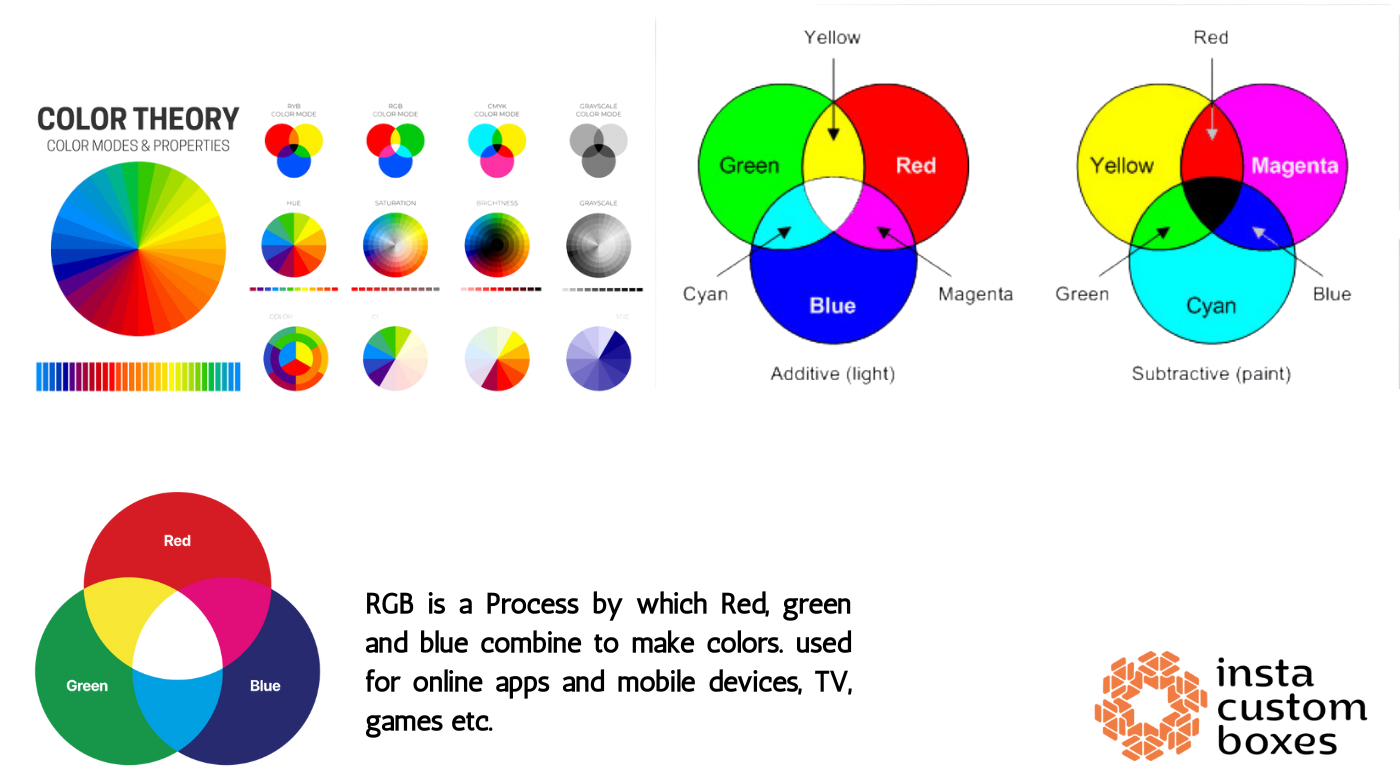

The term RBG defines Red, Green, and Blue colors for printing. These fundamental colors work well when working digitally. Typically these colors are best for smartphones, TV displays, laptop screens, megapixel cameras, and scanning devices, etc. However, the method of color balancing in RGB is a supplementary process.

How do RGB methods work?

It is the standard color profile for all digital material. The color is produced by combining red, green, and blue light sources in an object (such as a display) and adjusting how bright they are.

The color is initially dark, to which red, green, and blue light are applied successively. So. it can enhance and produce the most ideal pigmentation. Pure white is the result of combining all the colors at the same intensity.

Files Format For RGB

The world of technology provides various levels of red, green, and blue light to a starting point of darkness. It is excellent for producing the color digital image for screen displays.

However, it is not suitable for the printing of custom packaging boxes. You will be able to completely alter all three fundamental colors' levels of strength, oversupply, and coloring as an artist.

If you want to simply display your photographs digitally, RGB colors are the best choice. Animated, motion-capturing gifs and JPG and PNG photos are examples of standard file formats.

The Role of RGB In Printing

Printers really utilize a subtraction color paradigm known as CMYK, therefore RGB has no application for printing. The acronym CMYK denotes cyan, magenta, yellow, and black (key).

The CMYK coloring method involves taking huge volumes of cyan, magenta, and yellow ink off of white paper in order to generate different colors.

A color becomes brighter as more of that color is put into the ink. Black is created when all three colors are combined to their maximum intensity. White results from not giving any ink.

However, printers are unable to provide vibrant, vivid hues as laptop displays do. Therefore, we cannot use the RGB method for packaging printing.

The reason is that the variety of colors that printers can create is presumably restricted by the actual ink that they employ.

Where RGB Executes Better Results?

As it is mentioned earlier the RBG method best complements online media. Therefore, you can get stunning results from this method on various websites and application designs while creating illustrations, keys, tabs/icons,

Moreover, it gives excellent results for online advertising media like brand logos, and other marketing approaches. Furthermore, you can use this method to craft visual social media posts like profile photographs, profile backgrounds, and post photos

Also, It is the best option for producing visual content like graphic images, animations, infographics, and other computer graphics. Additionally, you can get vivid images for applications, social networking pages, and web pages.

Reasons To Avoid RGB Method In Printing

RGB should be eluded when printing on personalized Cardboard Boxes for packaging for the following reasons:

1: Color Spectrum

Relative to the variety of colors that can be easily developed on a PC, the spectrum of colors that are possible to print in made-specific boxes is less. The reason for this is that printers use chemical colors, which can put limitations on the range of colors they can produce.

2: Consistency

The next reason is the color consistency. Since RGB is a device-dependent color model. So, the colors appear differently on different devices. Therefore, it will be difficult to guarantee that the color consistency in the form of prints on your custom box packaging will be exactly the same on digital screens.

3: File Compatibility

The next issue is file compatibility. RGB files are not compatible with printers. Therefore, you have to convert your RGB files to CMYK for box printing. The entire process will be time-consuming. Additionally, won’t guarantee to give you exact results in the end as results in color shifts can vary.

4: Precision

Reproducing RGB colors in printing on custom-printed packaging is an uphill battle. This is due to the fact that printers use a traditional subtractive coloring approach, whereas computer displays employ an additive color model.

5: Light Stability

Compared to CMYK colors, RGB colors are more volatile in light. Therefore, RGB colors have a higher probability of fading or changing color over time, particularly when subjected to UV or daylight. The reason is that RGB colors use light addition. However, you can get CMYK colors by subtractive pigment blending. Consequently, CMYK colors exhibit greater resistance to fading and degradation.

6: Cost

Compared to producing CMYK colors, putting RGB colors on Custom Packaging Boxes for goods might seem more opulent. This is because RGB coloring frequently calls for additional ink to be used.

The Bottom Line

Although RGB is a fantastic color substitute for digital proofs. However, it is not best for box printing as it can not give you excellent printing results. You need to color conversion from RGB to CMYK when you need an image in print form but it won’t give you as crisp results as on electronic devices. The RGB method gives the best results on screen and is not compatible with printed devices.

Hope you like this great insight on the RGB color model. Keep following Insa Custom Boxes for more interesting blogs.